N Jewellery Techniques (NJTPL) was established under the able guidance of NARIMAN H. WADIA, a well-known figure in the jewellery industry since the last 56 years. It is currently being headed by its Director, MEHERNOSH D. PRINTER. When NARIMAN H. WADIA, entered into the jewellery industry, jewellery was traditionally being manufactured manually with obvious constraints. With his revolutionary application of ideas and introduction of machines for mass production of jewellery, NARIMAN H. WADIA provided a quantum leap in production capabilities and quality. He has several credits to his career. Having studied jewellery design at the London County Council Central School of Art, he served on the Research and Development Committee of the GJEPC and is currently a nominated appraiser of the Trade Advisory Panel for the Gold Jewellery by the Commissioner of Customs (Airport).

MEHERNOSH D. PRINTER, who started his career as an under-study of Nariman H. Wadia, gained a strong knowledge of jewellery manufacturing processes first hand, from his mentor, accumulating valuable experience in all aspects of jewellery manufacturing over several years. In addition, he has a strong educational background in Finance.

N Jewellery Techniques (NJTPL) gives consultancy for setting up complete factories for jewellery manufacturing companies from inception to completion, as also assists in solving problems related to all jewellery manufacturing processes.

In addition NJTPL also represents some of the finest machinery manufacturers worldwide for every aspect and stage of jewellery manufacturing, selectively choosing the best equipment available for the specific needs of our clients for the present and foreseeable future.

NEW - With the world now adopting 3D Printing in virtually every imaginable field, the application of Laser Sintering and 3D additive printing was inevitable in the jewellery field. NJTPL also brings in current leading companies having the above technologies to its esteemed clients. As technology develops further, we will proactively introduce the same periodically to our clients.

At present, NJTPL enjoys a major share in the market for :

At present, NJTPL enjoys a major share in the market for :

Welding Lasers from SISMA S.p.a., Italy - Various models for welding silver, gold, platinum, which can work continuously (In-built heavy- duty chiller system) for up to 22 hrs. per day for assembly, repairs, and welding of parts.

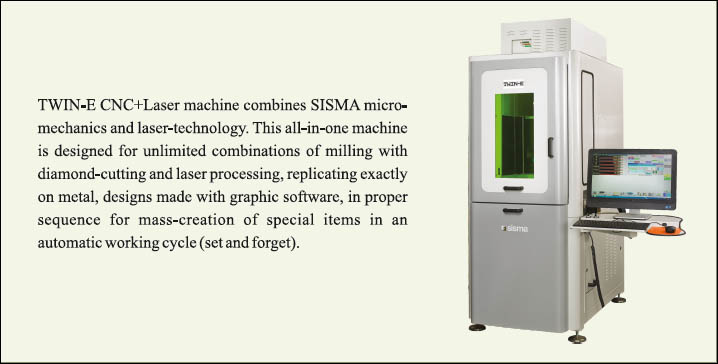

Marking Lasers from SISMA S.p.a, Italy - Various models can mark text, pictures, logos, etc,. on flat, curved and round surfaces with automated Rotary systems. Thinnest Laser beam of 10 microns.

Rhodium Plating Chemistry from Umicore Galvanotechnik GmbH, Germany - Brightest plating processes for everlasting brightness and problem - free chemistry. All assistance provided for setting up the plant up to the finished product, for plating departments.