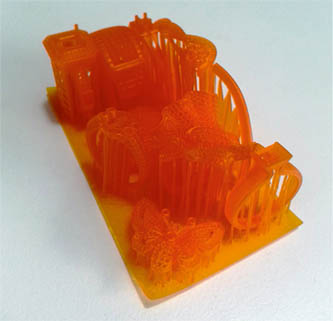

3D Printing is a revolutionary technology that is rapidly transforming the jewellery landscape. From design to production to retailing, the 3D Printing wave is sweeping across the industry and promises to become the de facto process in jewellery design & manufacturing. 3D Printing machines build 3D objects (rings, pendants, bangles, murtis) directly from CAD models. They do this by digitally slicing the 3D model into thin layers which the machine then builds one layer at a time to make the physical object. These models are made of a variety of plastic resins, wax, and directly castable resins. These prototypes can then be used for investment casting and other metal production processes.

3D Printing brings major advantages:

- Create impossible, never-seen-before designs or highly customized pieces, even if its just one.

- Make them in record time - hours to days only

- Save huge on development and production costs

- Develop lean and flexible business processes

Imaginarium has pioneered the use of RP and 3D Printing technologies in India since 2009 and is the largest 3D Printing service bureau in India. We currently serve over 2,500 business partners across the globe. In addition to having the broadest range of service offerings for jewellery product development, we also partner with you to understand your business and how best to implement 3D Printing into it, from machines & materials, to services & maintenance. 3D Printing brings the focus back on your imagination and creativity. Modern jewellers are required to innovate quickly, reduce lead time, and showcase broad, flexible portfolios. Customization is also becoming key to serving customers all over globe. It is precisely this environment that the power of 3D Printing can truly be realized. “ The rising price of raw materials has made the consumer and manufacturer deeply cost conscious. Adopting 3D Printing methods makes it possible to create contemporary, lightweight, and afforabale designs that economize material, withourt compromising on quality. In fact, the technology has truly levelled the playing field in terms of quality. Today, products made by bespoke designers, imitation jewellers, and plastic jewellery manufacturers, are comparable in quality – giving gold and precious metal manufacturers a run for their money. “

Imaginarium has pioneered the use of RP and 3D Printing technologies in India since 2009 and is the largest 3D Printing service bureau in India. We currently serve over 2,500 business partners across the globe. In addition to having the broadest range of service offerings for jewellery product development, we also partner with you to understand your business and how best to implement 3D Printing into it, from machines & materials, to services & maintenance. 3D Printing brings the focus back on your imagination and creativity. Modern jewellers are required to innovate quickly, reduce lead time, and showcase broad, flexible portfolios. Customization is also becoming key to serving customers all over globe. It is precisely this environment that the power of 3D Printing can truly be realized. “ The rising price of raw materials has made the consumer and manufacturer deeply cost conscious. Adopting 3D Printing methods makes it possible to create contemporary, lightweight, and afforabale designs that economize material, withourt compromising on quality. In fact, the technology has truly levelled the playing field in terms of quality. Today, products made by bespoke designers, imitation jewellers, and plastic jewellery manufacturers, are comparable in quality – giving gold and precious metal manufacturers a run for their money. “

A comparison of various 3D Printing technologies for jewellery prototyping