Diamond and jewellery industry has changed significantly over the last decade with variousnew innovations emerging in the field of technology, market potential and manufacturing competitiveness. It has become mandatory to be consistent with the continuous change in the market place. Customers are more knowledgeable, discerning and demanding than before. However, technology has played its optimum role in bringing up the change in the last decade but now; people need to enhance their own skills as well while identifying the possible wastes. At the same time, Changing times and increasing competition have highlighted certain issues. These issues demand for an improvement in enhancing optimum value, cut down costs and non value added activities between processes for increasing the productivity and quality and reducing the delivery time and production cost.

For tackling such issues, the concept of Lean Manufacturing is used as a production system that considers the expenditure of resources for any goal other than value creation for the end customer. This expenditure is considered as wasteful and thus, becomes a target for elimination. Lean manufacturing dates back to the post- World War-II era when Japanese automotive industry especially Toyota started re-building their infrastructure and resources. Till 1990, this concept was used only in automotive industry but since then, it has expanded to various fields such as aerospace, general manufacturing, healthcare, consumer electronics, construction, FMCG and more recently, the diamond as well as the jewellery industry. It focuses upon the elimination of eight wastes namely over-production, over-inventory, over-processing, waiting, rework/rejection, transportation, motion and unutilized human potential. However, in context with the diamond and jewellery manufacturing in recent times; RSM Astute has identified three additional wastes in the form of waste of information, underutilized technology and energy.

Lean represents a set of tools that assists in the identification and steady elimination of waste. As waste is eliminated, the quality improves while production cost and time are reduced. Apart from this, lean also focuses upon improvement in flow, smoothness of work, elimination of process unevenness, production leveling and pull production.

Lean represents a set of tools that assists in the identification and steady elimination of waste. As waste is eliminated, the quality improves while production cost and time are reduced. Apart from this, lean also focuses upon improvement in flow, smoothness of work, elimination of process unevenness, production leveling and pull production.

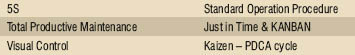

A list of lean tools for the diamond industry is given in the table below:-

RSM Astute Consulting is one of the approved Lean consultants (Empanelled by National Productivity Council, New Delhi) under the Lean Manufacturing Competitiveness Scheme of Government of India. RSM Astute has been facilitating Lean Manufacturing consulting service to Diamond companies over last 5 years.

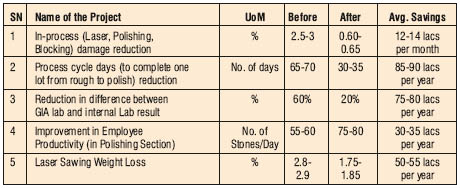

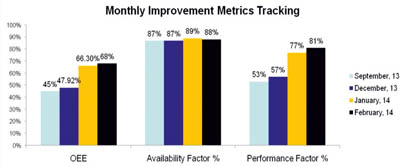

Summary of the key benefits out of the projects are highlighted below:

RSM Astute Consulting Group is the 6th largest accounting and consulting groups with group strength of 1000 + personnel in India and it is the sole Indian member of RSM International. We offer a wide range of service offerings which include International & Indian taxation Advisory, Internal/ Management & Statutory Audits, Operations & Process Consulting and Software Development & IT Consulting.

Contact us on Email: diamonds@astuteconsulting.com; Phone: 0261-3999600-619

Contact us on Email: diamonds@astuteconsulting.com; Phone: 0261-3999600-619

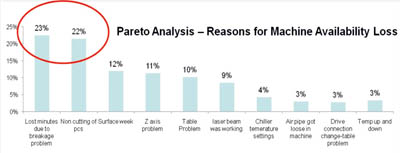

Organizations wishing to implement Lean Manufacturing have to undergo “Current State Value Stream Mapping” to gauge the areas of opportunity within their entire value chain Few pain areas identified in Diamond Processing units in general are as mentioned below:

- High Cycle Days to lot completion

- High Weight loss

- High Damage

- Difference in Planned vs Actual Results

- Lack of Resources Efficiencies

- Low Employee Productivity

RSM Astute has qualified as well as experienced team of Professionals that follows extensive implementation strategy in Diamond and Jewellery industry.