|

Technology Giants Earmark Investments in Research and Development  The global gems and jewellery industry has been growing at an astronomical pace in recent years, thanks to the importance given to key sectors such as Research and Development in the Technology and Machine tools segment by well known companies. Research and Development has not only resulted in the development of innovative techniques but also has elevated the gem and jewellery industry to the highest level of quality and precision. Technology and Machine tools have changed the way not only a manufacturer looks at a final product, but also has affected consumers’ preference. Today every consumer is looking at finesse and exclusivity in the product that he buys and is also willing to pay a premium for the same. Leading Jewellery designers of the world have acknowledged the role of technology in jewellery making and today most of the designs are exquisite only because of the interference of technology in the final product. Every technical process from Mine to Market involves technology and Machine tool expertise, be it refining of precious metal, to polishing of the precious stone, or moulding and setting involved in jewellery making. Packaging too has evolved and is playing a vital role in the sale of jewellery, all thanks to the advent of innovation in technology.

The global gems and jewellery industry has been growing at an astronomical pace in recent years, thanks to the importance given to key sectors such as Research and Development in the Technology and Machine tools segment by well known companies. Research and Development has not only resulted in the development of innovative techniques but also has elevated the gem and jewellery industry to the highest level of quality and precision. Technology and Machine tools have changed the way not only a manufacturer looks at a final product, but also has affected consumers’ preference. Today every consumer is looking at finesse and exclusivity in the product that he buys and is also willing to pay a premium for the same. Leading Jewellery designers of the world have acknowledged the role of technology in jewellery making and today most of the designs are exquisite only because of the interference of technology in the final product. Every technical process from Mine to Market involves technology and Machine tool expertise, be it refining of precious metal, to polishing of the precious stone, or moulding and setting involved in jewellery making. Packaging too has evolved and is playing a vital role in the sale of jewellery, all thanks to the advent of innovation in technology.Jewellery industry is probably only second to Information Technology sector [IT] when it comes to investment in Research and Development.  Leading Machinery, Technology and Education companies of the world from the jewellery sector are earmarking huge investments in their respective R&D departments for continuous research and come out with state of the art tools that not only will save time of production but also help in accurate determination of the ‘subject’ which in turn will determine perfect ‘pricing’ of the final product. Be it Gld, Platinum, Diamond or Color gemstones, Technology helps in determining the product quality, achieve finesse in production which saves time, effort and money in the process of manufacturing and ultimately helps derive pricing of the finished product.

Leading Machinery, Technology and Education companies of the world from the jewellery sector are earmarking huge investments in their respective R&D departments for continuous research and come out with state of the art tools that not only will save time of production but also help in accurate determination of the ‘subject’ which in turn will determine perfect ‘pricing’ of the final product. Be it Gld, Platinum, Diamond or Color gemstones, Technology helps in determining the product quality, achieve finesse in production which saves time, effort and money in the process of manufacturing and ultimately helps derive pricing of the finished product.Some of the classic examples of recent Research products are ‘Synthetic Diamond determination Machine, introduced by GIA, Diamond counting machine by HRD Antwerp, Rhodium processing technology by Nadir Metals Turkey etc. These innovations have truly transformed the very essence of manufacturing by easing out many a process involved in the production of a finished product. Global consumers are getting a taste of the best quality and exclusively crafted products which is now a norm. Technology has also compensated the growing Gold rates and Diamond prices by intervening the production process. Light weight Jewellery is a result of cutting edge technology. Leading manufacturers of the world have been successful in launching ‘light weight jewellery products’, be it chains, necklaces, bangles or any other due to the usage of highly quality precision equipments. Light weight jewellery have also become the most sought after by budget consumers. Diamond wastes due to cutting and polishing have also found good use in the making of jewellery. In this story the JTM bureau has profiled important companies in the Technology and Machine tool segment, some of whom with sheer passion for research and development have introduced state of the art products that would go a long way in transforming the Global Gems and Jewellery industry. |

April-June 2014

|

April-June 2014

High-tech and traditional tools

Since many of years the diamond manufacturing industry has been an industry were craftsmanship took an important place in the creation of a perfect diamond. However, the last 20 years, more and more high tech tools, such as rough and polished planners, laser sawing and shaping machines, gemmological instruments and auto blocking devices , succesfully earned their place in the proces. One might say that total automatisation of diamond manufacturing is nearby. This could be if the quality standards of the polished diamond would have kept their old values. But the market requests higher quality of make. Triple-X, flawless cut, with an impeccable smoothness are nowadays the key words. This sets the bar high, aspecially on the finishing or brillanteering side. There is no device yet wich can replace the soft touch, the sensitive reaction or the apprehension of the human hand and mind. The workers skills makes half of the result, a perfect polishing tools provides the second half. Let's put it this way, a precious

diamond deserves only the best of polishing tools. Since over 65 years, Rico Tools Belgium fulfils this commitment.

Since many of years the diamond manufacturing industry has been an industry were craftsmanship took an important place in the creation of a perfect diamond. However, the last 20 years, more and more high tech tools, such as rough and polished planners, laser sawing and shaping machines, gemmological instruments and auto blocking devices , succesfully earned their place in the proces. One might say that total automatisation of diamond manufacturing is nearby. This could be if the quality standards of the polished diamond would have kept their old values. But the market requests higher quality of make. Triple-X, flawless cut, with an impeccable smoothness are nowadays the key words. This sets the bar high, aspecially on the finishing or brillanteering side. There is no device yet wich can replace the soft touch, the sensitive reaction or the apprehension of the human hand and mind. The workers skills makes half of the result, a perfect polishing tools provides the second half. Let's put it this way, a precious

diamond deserves only the best of polishing tools. Since over 65 years, Rico Tools Belgium fulfils this commitment.In the late sixties, RTB launched with great succes the first Rico dop with endless facet screw, a big improvement for its time. Many changes later the D265 series (excellent dops) and the D420 series ( Quick Step dops) have proven their reliability in a large number of factories the world over. We at Rico Tools Belgium believe that their always will be room for the traditional equipment in a perfect joint venture with the automated tools. It is still an trilling idea to know that part of your precious diamond is created by the hands of a artisan. Located in Belgium at the cradle of the diamond industry, Rico Tools is a third generation company with a broad experience and a strong reputation. Like to learn more about us and our products, feel free to visit our webshop at www.ricotools.be

|

April-June 2014

|

April-June 2014

is the call of the Day

S. Tirupathi Rajan MD - Goldsmith Academy Pvt. Ltd. The market is taking a balance in the multidimensional forces: price or cost, ability to buy, design variations, volumes, refurbishing or exchanges and marketing. The only solution to maximize the business of craftsman or goldsmith or the manufacturer amidst these forces is the Technology. Technology plays role in all cycles of jewellery manufacturing: designing, melting & drawing, refining, dye or mould making, casting, testing and fixing, electro plating, enameling, carving & stone fixing, assembling; consumers want even virtual simulation of the suitability of the design to her before even the production for which software’s are extensively available; as the market is open consumers want absolute transparency and freedom to trade her product without getting locked to a vendor or retailer, there comes the BIS standards and the technology such as measurements such as weight, metal composition and assessment without destructive testing have proven to be highly possible and viable using laser scans. To be more categorical, machineries – mechanical, electrical, electronic including software applications – are essential element for anyone in this market to be sustainable and profitable.  The days are not too far to say the as we have in food industry – ready to cook or eat – or just in time paint manufacturing or tailor made garments - we will soon see the days of design to product in minutes or hours as tailor made becoming an option for new market space in Indian consumer markets using rapid prototyping or manufacturing machines available in the retail counters at their backyard workshops. Soon adaptation to technology will be the underlying vehicle for any skilled artisan or manufacturer or retailer in this market in India, which will behave differently from any gold jewellery market in the world, unlike many industries are impacted by westernization but jewellery will not be. So start and go for mechanization and automation as much as you can. Every Rupee investment will get you 30% more cost savings and profit improvement in your business.

The days are not too far to say the as we have in food industry – ready to cook or eat – or just in time paint manufacturing or tailor made garments - we will soon see the days of design to product in minutes or hours as tailor made becoming an option for new market space in Indian consumer markets using rapid prototyping or manufacturing machines available in the retail counters at their backyard workshops. Soon adaptation to technology will be the underlying vehicle for any skilled artisan or manufacturer or retailer in this market in India, which will behave differently from any gold jewellery market in the world, unlike many industries are impacted by westernization but jewellery will not be. So start and go for mechanization and automation as much as you can. Every Rupee investment will get you 30% more cost savings and profit improvement in your business. While doing so technology transition becomes a big challenge for the players. In jewellery industry in India transition works in 5 steps; education, trials, implementation, improvement and proficiency; generally it takes 2 years of sustained effort by oneself to reach the proficient level of using technology in this trade. However transition has a cost which has to be treated as investment by the player rather not to look at it with short sightedness. With gold price going up always in long run, as with economy, it must be noted by the player that the transition cost will be very less today as compared to technology transition cost after few years; this is a major difference between the jewellery industry and other traditional as well as modern industries. So why wait?

While doing so technology transition becomes a big challenge for the players. In jewellery industry in India transition works in 5 steps; education, trials, implementation, improvement and proficiency; generally it takes 2 years of sustained effort by oneself to reach the proficient level of using technology in this trade. However transition has a cost which has to be treated as investment by the player rather not to look at it with short sightedness. With gold price going up always in long run, as with economy, it must be noted by the player that the transition cost will be very less today as compared to technology transition cost after few years; this is a major difference between the jewellery industry and other traditional as well as modern industries. So why wait?It is recommended for every player, which most of them are in traditional manufacturing or trade practices, to take an experienced consultant; we strongly recommend to the industry to adapt lean manufacturing as well as kaizen principles in their operations, no matter of their size or level of operations. The transition investment shall be more optimal if the transition are planned and designed along these lines. Goldsmith academy is committed along with Friday Micro Ventures for the welfare of the traditional jewellery manufacturing industry in India for the competitiveness of the millions of goldsmiths in the modern market. You can write to us at E-mail:- goldsmithacademy2012@gmail.com |

April-June 2014

Manufacturing and Finishing

Nickunj has indeed come a long way. Since the inception of our journey, 30 years ago, there has been no looking back. Dotted with milestone achievements, our product-oriented company has now earned its place as an end-to-end solution provider in the engineering domain. We are the largest manufacturers of EDM wires in India and I am justifiably proud to say that we catalyse paradigm shifts in business activity. Nickunj has taken on some of the most daunting challenges in its stride, and the ability to offer unparalleled solutions in any situation within this realm has helped us carve an eminent niche for ourselves. Inspired by global manufacturing giants, we provide unstinted technical and commercial support, and this has enabled us expand our customer base. Prudently chosen products across all industrial segments have helped us enlarge our reach, and also help us hedge against significant sluggish industry trends. A full-fledged Technical Support & Service Centre providing prompt, efficient and unmatched servicing solution. Our quest in bringing the latest globally proven technology to Indian shores has helped us stay miles ahead of our contemporaries. Recently, we have consolidated and reorganized various business divisions under 5 specific SBUs. We now emphasize that 'Catalysing Transformation' of businesses remains our single point agenda. Not resting on our past laurels, new tie-ups with reputed global companies allow us to accelerate growth, in turn transforming your business. We solicit a catalytic role in your progress and invite you to experience the multitude of products, services and solutions offered by us. 1. The Power of Light Weight Jewelry : (cadmium free Electroforming) Nickunj Eximp Entp P Ltd together with a patented technology services provider have launched an entire new dimension o f turnkey solutions on Electroforming jewelry, which can be hall marked and has robust construction giving it an edge over the conventional casting and handmade jewelry. In a unique method developed jointly with the help of Indo-Italian Collaboration, the products can now be electroformed in different KARAT compositions, Plated, Engraved, and also linked and assembled just as any other Jewelry parts. With this Revolutionary Technique & Imagination of the Jeweler the scope of wearing spectacular looking Jewelry can be brought well within the reach of working class buyers not compromising the confidence of wearing Real Gold certified jewelry with a technology feature. The entire setup, training and product quality guarantee is bundled up into one project and comes with professional after sales support, selection of right raw material and chemicals to give the most consistent results with assured daily production quantity output. India is a country where the size of jewelry worn leaves a lasting impact on the mind of the beholder. It talks about the preferences of a person and also talks about how aware a person is about the current trends in Jewelry manufacturing technology. We at Nickunj Eximp back this project with our team of experts in the field of Consumables and tools needed for the brightest finish of electroforming jewelry which will stand apart in any competitive presentation. 2. Nano Technology in Plating Nickunj Eximp Entp P Ltd has recently Launched Ground breaking technology in providing Plating solutions which make plating of chains and Bracelets look very easy and simple. We offer a colorful collection of Plating solutions ranging from Chocolate Brown, Matt Silver, Palladium Black, Rose gold with International look and Yellow in 4 different shades. 3. Anti Tarnish for Jewelery articles Introducing guaranteed Anti Tarnish Solutions for Silver ware, Silver jewelry and even Gold jewelry. 4. 3D Printing Technology Tremendous value can be gained by jewellery designers and manufacturers that utilize desktop 3D printers as fashions in this industry change rapidly our solutions tackle the major challenge of ‘response time’, unleashing the latent creativity in your design studios. The High resolution and best-in-class casting materials of the Kevvox 3D printers, combined with ease-of-use result in the ability to create multiple designs at the lowest pre-production costs. Kevvox 3D printers are the fastest in the industry resulting in greatly increased productivity. Needless to say, our intelligent, integrated software helps you to achieve precision and accuracy. We invite you to visit us at the IIJS 2014, a B2B event in the month of July, to be held at NSE grounds, Mumbai. |

April-June 2014

for Jewellery Making Machinery

& Tools

April-June 2014

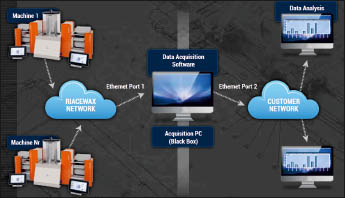

Riace Data Acquisition  Riacetech Undeniable skill in constructing and patenting innovative wax injectors that can be totally controlled , programmed and connected to the company network , Is further enhanced with Riace data acquisition . Ones installed on a computer connected to the network this software acts like a “spy” and silently monitors and records everything the machine is doing . It is a kind of” black box”. The collected data are then filled and available in Microsoft access (or MySQL, SQlite etc) and/ or CSV( Compatible with Microsoft Excel ) formats . with this information , the company can analysis production , discover where any defects in the waxes originate and find the reasons for waste production, thus controlling the efficiency of the machinery and the moulds..

Riacetech Undeniable skill in constructing and patenting innovative wax injectors that can be totally controlled , programmed and connected to the company network , Is further enhanced with Riace data acquisition . Ones installed on a computer connected to the network this software acts like a “spy” and silently monitors and records everything the machine is doing . It is a kind of” black box”. The collected data are then filled and available in Microsoft access (or MySQL, SQlite etc) and/ or CSV( Compatible with Microsoft Excel ) formats . with this information , the company can analysis production , discover where any defects in the waxes originate and find the reasons for waste production, thus controlling the efficiency of the machinery and the moulds..

Mono Intuitive

Inextensible Mono station injector. Equipped of one melting tank, one vacuum meter for checking the vacuum inside the mold, RFID microchip reader is included. Micro syringe of 12 cmc with final setting up of the temperature and centering clamp with plates 120x90x8―>45* mm.  Bi Hydro Injector with two independent inextensible working stations. Equipped of two melting tanks for the simultaneous use of two types of waxes, vacuum meters for checking the vacuum inside the mold, RFID microchip reader is included. Micro syringe of 12 cmc with final setting up of the temperature and auto centering clamp with plates 120x90x8―>45* mm.Machine: 58 kg - 90x38xh53 cm / Wooden box: 90 kg - 121x47xh70 cm.(*) for special request plates 120x120x23x60 mm. |

For Demonstration and enquires please contact TSS Tech Ph: 0091-22-69988899 / 0091-8976093721 Email :tom@trinityworld.in |

April-June 2014

Dust Burning & Gold Melting

For Demonstration and enquires please contact Ph: 022-30880201 /40260993/65731943 Email : parag@riddhiheatron.com Web Site: www.riddhiheatron.com We are manufactures of all types of furnaces • Burnout furnace • Air circuiation burnout furnace • Rotary burnout furnace • Electric dust burnout furnace • Gas dust burn out furnace • Anneayling furnace • Assying furnace • Stone treatment furnace • Resistance gold melting, machine • Induction gold melting furnace • Non - cyanide electrolytic Stripping machine |

April-June 2014

-Achieving excellence through quality service

The Group has over 20 years of experience of conceiving, developing and managing successful businesses across various business sectors in the Indian as well as International markets. The Group's Business currently is diversified into four industry sectors - Jewelry, Pharmaceuticals, Printing and Packaging & Real Estate. “Today we continue to explore opportunities through alliances to draw maximum value from each strategic arrangement.” Today Rank in jewelry sector is a leading Manufacturer, Importers and Distributors of Precious Metals products viz. Pendant Chains, Jeweler’s Findings & Mountings, Bullion, Master Alloys, Inverness - Safe Ear Piercing System to the Indian Jewelry Trade - both in Domestic as well as in SEZ's - Duty Free Zone in India. Product Profile Quality Findings: 1,000 different types of findings is available in all karatages. Our wide range of findings will give you the convenience to design your jewelry hassle free. If our range does not satisfy your requirement we are there to develop it for you. Range Of Product: • Attach rings • Cuff link backs • Ear wires • Pendants loops • Safety catches • Beads • Ear clips • Joints • Pin stems • Settings • Chain ends • Ear nuts • Jump rings • Shanks • Snaps • Clasps • Ear posts • Pendants • Solitaire rings • Solder • Spring rings • Tubing.... Important features: Widest range of best quality findings available to meet every jewelry manufacturer's need. Available in various choice of metal - Gold (Y/W) - 9K,10K,14K,18K & 22K, Platinum, Sterling Silver, Gold Filled, Brass….Light & Consistent in weight. Our Finding has, and hold, an exquisite finish. All findings are carefully scrutinized to ensure them to be free from defect. Master Alloys: The use of a plain mixture of metals by our goldsmiths is being replaced steadily by master alloys which is scientific formulation of metals which supports the new casting methods of jewelry making. If you want your jewelry to be made in multiple pieces, designs and colors without compromising on the quality, strength and weight then ‘master alloys’ are your key to success. We at rank international, try to provide the jewellery industry with the best quality master alloys with a huge range of alloys. We try to suit all types of requirements in regards to colour, strength fashion and designs, tarnishing, industry standards and economy. We are regularly engaged in R&D to develop new alloys to suit industry demands and customer requirements. We not only manufacture alloys but also provide our customer with technical help for trouble shooting any problem associated with our alloys. Important features: Enables to arrive at different karats and colours of gold. Reduces gold loss improves work ability for hand & casting work. Consistency in colour & finishing. Master alloys are prepared under strictly controlled conditions using high purity metals leading to uniform compositions and international standards. Avoids porosity and cracking. Special alloys can be developed as per customer specific need. Chains: A pendant always needs a companion and let us help you to find that perfect match. An impressive variety of chains of different lengths, thickness, designs and karats are available with us. A collection that will satisfy any need of yours and if not then we are always there to customize it for you. Let it be silver, gold or platinum with special clasps, tags or a customized assembly we can offer it all. Range Of Product: • Bead • Bismark • Cable • Curb • Rolo • Singapore • Rope • Snake • Venetian box • Wheat & many more.... Important features: All popular lengths in stock. Special clasps, marking tags, custom packaging. Soldered end rings. Available in various choice of metal - 9K,10K,14K,18K & 22K, Platinum, Sterling Silver. Custom make & hold programs. National sales coverage. Low cost shipping rates - fully insured. Specialized distribution programs. Piercing Systems: Inverness system is the safest and most technologically advanced ear piercing system. It offers uncompromised safety and sterility. Inverness fully encapsulated ear piercing earrings guarantee the safest ear piercing by guarding against contamination and the patented Safety Clutch (earring back) eliminates the risk of scratching the area behind the ear. Jewellery Care: Rank have a wide range of jewelry care product. One from it is ‘Briliant Jewelry Care’ In compliance with this fundamental principle, we present the industry’s first jewelry cleaning spray. It is used by some of the very famous celebrities of the world. Its fast, safe, easy & versatile product for Jewellery care. It’s fast! Get rid of jewelry cleaning schedules. it is a spray on rinse off jewelry cleaner, which works in one minute. Better than others! It is superior to other cleaners as it removes hard water deposits from the jewels. Cares while it cleans! it has the same PH as an orange so it is safe to use on gold, silver, platinum and most gemstones. It’s active ingredient is so safe that it is used in common items.   QUALITY is the key word in the current changing economy. We understand that the quality of products is the paramount goal and as a constant endeavor to maintain or improve the quality of the products marketed by us. Every effort is made to ensure the highest level of customer satisfaction. Our constantly expanding product line makes our selection impressive indeed. The company within a span of two decade, due to its dedicated hard work and prompt services, has been able to build a name of pride and reputation for itself in the Jewelry Industry. Company don't only measure success in financial terms but also how we achievethe results is important. We work hard to conduct business with integrity - respecting our employees, our customers, our principal suppliers and the environment around us. This is our company's road to sustainable, profitable growth for our business and long-term value creation. For more information on the latest product you can visit us at www.rankinternational.com or email at sales@rankinternational.com |

April-June 2014

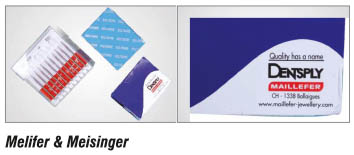

Bringing International Technology to the

Jewellery Industry

The Amrit Group established in 1984, owned by Mr J.P.Khandelwal, a qualified and highly experienced engineer, has emerged as one of the most prestigious and dynamic company of recent times in manufacturing, importing and exporting of Diamond studded Gold and Platinum Jewellery, processing and polishing of Diamonds from 0.50CTS and above, and one of the Worlds leading manufacturers of gold refining plant namely Amrit precious metal refiners and Gold assaying equipments. Recently the company has started manufacturing and marketing XRF PRECIOUS METAL ANALYZER. Mr. Naresh Balani, the driving force behind the company, has an industry experience of more than 25 years and has developed skills with some of the best names in the trade. AMRIT GROUP manages the most complex situation of jewellery, diamond trade and precious metal refining and assaying technology with a team of talented jewellers, technicians and engineers who strive to produce new designs each month thus ensuring continuous selection to suit the tastes and preferences of global consumers, besides creating jewellery and precious metal refiners for clients as per specifications.

The Amrit Group established in 1984, owned by Mr J.P.Khandelwal, a qualified and highly experienced engineer, has emerged as one of the most prestigious and dynamic company of recent times in manufacturing, importing and exporting of Diamond studded Gold and Platinum Jewellery, processing and polishing of Diamonds from 0.50CTS and above, and one of the Worlds leading manufacturers of gold refining plant namely Amrit precious metal refiners and Gold assaying equipments. Recently the company has started manufacturing and marketing XRF PRECIOUS METAL ANALYZER. Mr. Naresh Balani, the driving force behind the company, has an industry experience of more than 25 years and has developed skills with some of the best names in the trade. AMRIT GROUP manages the most complex situation of jewellery, diamond trade and precious metal refining and assaying technology with a team of talented jewellers, technicians and engineers who strive to produce new designs each month thus ensuring continuous selection to suit the tastes and preferences of global consumers, besides creating jewellery and precious metal refiners for clients as per specifications.Indian consumers operate with two contradictory mindsets when deciding to buy a piece of jewellery. “At heart most of the Indian consumers remain quite rooted in culture and tradition and continue to value jewellery as a time honoured possession. On the other hand, the same consumers exhibit contemporary urban traits and see trendy jewellery as an extension of their personality and lifestyles. “We opt for various brands thereby emphasizing their perceived worth accorded to a piece of jewellery”, says Naresh Balani. The jewellery buying pattern in the Indian market is also changing, says he, adding Indian jewellery fashion does not surrender to the burdens of fall winter or of a spring summer influence. In India consumers stick to their personal tastes. It could also be because most of them cannot afford the routine makeover of the wardrobe. He finds another interesting feature. The Indian consumer looks for the longevity in a product. Hence the product supersedes the season. If you are looking for something unique and want a jewellery piece designed to your own specification and perfection then look no further, AMRIT GEM TECH PVT. LTD. team has years of experience in processing your design into Perfect Diamond studded Gold or Platinum Jewellery.  AMRIT GEM-TECH PVT. LTD. has been bringing the latest in International technology for goldsmiths, to the global Gem & Jewellery industry. There services in the highly specialised field of automatic chain manufacturing and investment casting are widely acknowledged. The Amrit Group established in 1984 has emerged as one of the most prestigious, dynamic and one of the Worlds leading manufacturers of gold refining plant namely AMRIT PRECIOUS METAL REFINERS. The AMRIT PRECIOUS METAL REFINER comes in various capacities from 1 kg. to 6 kg. of carat gold scrap, filling, polishings, dust, workshop sweepings etc.

AMRIT GEM-TECH PVT. LTD. has been bringing the latest in International technology for goldsmiths, to the global Gem & Jewellery industry. There services in the highly specialised field of automatic chain manufacturing and investment casting are widely acknowledged. The Amrit Group established in 1984 has emerged as one of the most prestigious, dynamic and one of the Worlds leading manufacturers of gold refining plant namely AMRIT PRECIOUS METAL REFINERS. The AMRIT PRECIOUS METAL REFINER comes in various capacities from 1 kg. to 6 kg. of carat gold scrap, filling, polishings, dust, workshop sweepings etc.Salient Features: • Unit complete with fume cabinet & S. S. stand. • Fume scrubber with inbuilt Three Phase/ Single Phase blower. • Tank with motor for re-circulation of water. • Safety bottom tray. • Refines carat gold scrap, filling, polishing, workshop sweepings dusts etc. • Hazardous fumes and odours, neutralized through gas treatment system. • Specially Designed filter barrel for quick filtration. Traps all solids, even from thick slurry. • Virtually 100% recovery. Very high purity can be achieved. (999 or more). • Can be used for Gold & Silver refining. Based on the internationally adopted method of refining, the AMRIT REFINER has incorporated further improvements to suit the refining needs of the jeweller and refiners all across the globe. With there own research and development facilities, indigenous manufacturing capability and service network, they provide proper training and prompt after-sales service, besides providing specialised consultancy for specific requirements of clients. Training in operation of equipment and refining, provided at factory prior to despatch of the equipment, makes the AMRIT REFINER are very easy to use. The step by step instruction manual and DVD, which comes with the system, provides further guidance. All chemicals and consumables are readily available in respective local markets. With the AMRIT REFINER, you can obtain fine gold from carat gold scrap, filings, polishings, dust, workshop sweepings etc., in your own premises, under your total control, in very short time, this results in substantial savings, due to low operational cost and complete recovery, without paying to outside refiners. Precious metal is fully recoverd in powder form, ready for melting. Hazardous fumes and odours are neutralized before being discharged into the atmosphere, maintaining a clean, healthy working environment. |

April-June 2014

A Trusted Name in the Field of Jewellery

Jewellery is a very fascinating term. It has a lot of sparkle in it. It is a fashion statement for ladies and a matter of fortune for gentlemen. Do you know a lot of labor, creativity and hard work go in making these beautiful pieces of art? It all starts with melting of precious metals like GOLD, SILVER etc.

Jewellery is a very fascinating term. It has a lot of sparkle in it. It is a fashion statement for ladies and a matter of fortune for gentlemen. Do you know a lot of labor, creativity and hard work go in making these beautiful pieces of art? It all starts with melting of precious metals like GOLD, SILVER etc.Jewellery is not manufactured with 100% Gold or Silver. These metals are very soft and some alloy additions are required to increase hardness and other properties. Garg Electroheat are importers and sole selling agents of Gallorini brand alloys and solder powders from Gallorini snc, Italy. Jewellery manufacturing is associated with metal refining to recirculate old metal and the scrap metal. Garg Electroheat represents Italimpianti Orafi spa, Italy for their refining and casting machines.

It is seen that LPG is used for jewellery production in the form of soldering and brazing torches. This method of soldering and brazing is very hazardous for workers as well as very risky for storage. A very environment friendly way to generate flame is from disassociation of water in oxygen and hydrogen. If hydrogen is burnt in presence of oxygen it emits water vapors which are not harmful for health at all. Garg Electroheat are representative for McPhy Energy, Italy for their Gas Generators. Go Green. As the value of Gold is increasing every day people have started looking for alternate jewellery. Platinum is now within reach of common people. Garg Electroheat are sole selling agents for Hot Platinum South Africa for their range of Platinum Group Metal melting and casting machines. Garg Electroheat is a sister concern of Garg Overseas wherein we manufacture a range of Induction Gold Melting and casting machines. Garg Electroheat is regarded as one of the trusted leading manufacturer of Induction Gold Melting Machines. We manufacture from 1 Kg to 20 Kg capacity Gold Melting Machines. We have hundreds of satisfied clients all over India and abroad.

Garg Electroheat is a trusted name for quality and service in jewellery field. It is headed by Rajesh Garg (BE Electronics, CPMHRM IIT Mumbai). He has experience of 10 years in working with some of the leading companies of the world in this field. Garg Electroheat is dealer and distributors for many world class machines for jewellery industry. We have also worked with the best names in this industry.  |

April-June 2014

Specializing in Cleaning Solutions

Our focus has always been to work on your needs, to help you work more productively and profitably as the Industry changes and competition expands in every Environment. Advanced technology and top of edge quality have been synonymous with the MICRO ULTRASONIC and we constantly work towards technical developments to gain High productivity and low maintenance, keeping in mind the price factor. A group of Qualified engineers and designer constantly upload the research of enhanced technological solutions. Today MICRO ULTRASONIC has developed a healthy growth in India and become a well known & Reputed Brand in Ultrasonic Cleaning Systems and Jewellery Machine Making Industry. All this work is only possible by our creative team work. We hope the range of product information contained meet your requirements. A UNIT OF MICRO ULTRASONIC Add.:-6, Mohd Amin Chawl, Behind Sagar Park, Amrut Nagar, Ghatkopar(W), Mumbai - 400 086. Tel:- 022-2500 1984 / 2500 3660. www.microultrasonic.net, info@microultrasonic.net, microultrasonic@gmail.com Visit us at ‘IGJME - 2013' Booth No: 17, 19 |

April-June 2014

Achieving high service levels through manufacture & distribution of quality machine tools

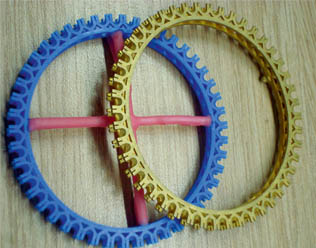

Arihant Enterprises was established in the year 2002, we are marching ahead in the market as a manufacturer of jewelry buff and brushes and Distributor of all kinds of jewelry consumable items and RTV Liquid Rubber etc. Our Tools and Machinery are of high quality and durability, thereby have received huge acceptance among customers. Winning their trust and establishing a strong market presence would not have been possible without our team members. Their hard work and commitment have allowed us in making a visible stand in the market.

Arihant Enterprises was established in the year 2002, we are marching ahead in the market as a manufacturer of jewelry buff and brushes and Distributor of all kinds of jewelry consumable items and RTV Liquid Rubber etc. Our Tools and Machinery are of high quality and durability, thereby have received huge acceptance among customers. Winning their trust and establishing a strong market presence would not have been possible without our team members. Their hard work and commitment have allowed us in making a visible stand in the market.Under the mentor ship of Mr. Bhavin Shah, we have succeeded in conforming to the industry standards. Under the brand name 9 Star we have significance presence in themarket. Marked for genuine work of art, we follow ethical business practices. Being a customer-centric firm, we are dedicated to customer service. Active in the industry since years, we have successfully accomplished in attaining our goals.  On the grounds of continuous research regarding the technical specification, required raw material, production process, testing parameters and others, we have earned complete expertise as the manufacturer jewelry buff and brushes, etc. Our team of experts and experienced professionals enable us to manufacture large array of products in a bulk and deliver them to our clients within stipulated time frame. Due to the effective performance, durability and resistance capacity our products are well admired by our clients.

On the grounds of continuous research regarding the technical specification, required raw material, production process, testing parameters and others, we have earned complete expertise as the manufacturer jewelry buff and brushes, etc. Our team of experts and experienced professionals enable us to manufacture large array of products in a bulk and deliver them to our clients within stipulated time frame. Due to the effective performance, durability and resistance capacity our products are well admired by our clients. Shin Etsu

Shin EtsuFeatures • Addition cure system • Good durability with polyurethane resins • Low viscosity • Moderate tensile strength • Low linear shrinkage • Room temperature cure or heat cure to shorten the curing time Application Mold making of intricate design models etc. |

April-June 2014

APX International. was in corporated as proprietorship concern founded in may 2013 by Mrs Apexa jain, under the dynamic leadership of Mr. Dipak Jain (having 21 yrs of rich experience in jewellery industry) & Mrs. Apexa Jain.The company has been consolidating its position in Indian Jewellery Industry. A complete professional approach blended with hard work & entrepreneurship has enabled the company to grow at a phenomenal rate since inception.

APX International. was in corporated as proprietorship concern founded in may 2013 by Mrs Apexa jain, under the dynamic leadership of Mr. Dipak Jain (having 21 yrs of rich experience in jewellery industry) & Mrs. Apexa Jain.The company has been consolidating its position in Indian Jewellery Industry. A complete professional approach blended with hard work & entrepreneurship has enabled the company to grow at a phenomenal rate since inception.Apx International focus on surface finishing for Jewellery applications and precision components, Vacuum pressure casting, Gold Refining Machine, SilverRefining Machine, gold bars & coins polishing to achieve optimum result with minimal handwork- saves precious metal losses. The company’s vision is not only predicting the future; but knowing the future and making it prosperous for every customer.It includes dedicated efforts, extensive research and knowing the needs of every customer.It is a preparation for the journey ahead; ahead of its time, and ahead of every competitor. The vision is to set new benchmark in providing quality products and help you achieve the success you desire.Every customer of APX International is its indivisible part, and every end eavour of APX International is to make this indivisible part the happiest part. Our Mission is to make an effort to accomplish objectives, and every mission of APX International is dedicated to its valued customers. The statement of perfection is incomplete without a soulful dedication towards work. |

April-June 2014

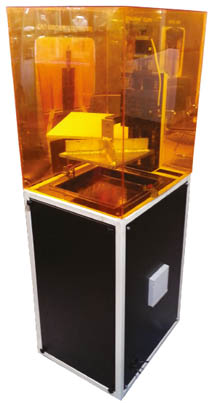

Ultra-Cam 3D Printer Highest Quality

Support for Production of Customised Jewellery

WE CAN build investment-casting wax models directly from CAD data, BY ULTRA-CAM 3D PRINTER. This is the best machine for production of customized jewelry with its unbeatable price, development speed and output quality. The ULTRA CAM can run a variety of materials for direct casting, hot rubber, and silicone molding. The machines are delivered and installed with all the relevant software and trainings to generate support and have a perfect model production. ULTRA-CAM offer the highest resolution in their class with build layers as fine as 10 micron.  Technical specifications:

Technical specifications:• X-Y resolution 37 microns. • Z resolution 10 microns. • Input 230 V. • Lamp life 4000 hours. • Built in platform 73 mm X 42 mm @ 37 microns XY resolution. • Accuracy : ±5μm/cm • Operating temperature : 0°-40° C Key Features: • Fast output. @ 60 mm /hour @ 50 microns Z axis lift. • Excellent accuracy (approved by leading jewellery making companies). • Best machine for filigree and micro prong work. • Very smooth casting can be obtained by ULTRACAM pieces. • Very user friendly software which help any unskilled labor to operate the machine. • Very low maintenance and running cost. |

April-June 2014

Jewellery Making Machinery & Equipments

Gold side production is an India based leading manufacturer and exporter of jewellery making machinery & equipments since 1992. The brand name of company is “LION GOLD SMITH”. The founder Mr. Dineshbhai Rabadiya has continuously strived to achieve excellence in qualitative production. Gold Side is in to manufacturing of Special purpose rolling mill, Tube forming machine, Jewellery polishing machine, faceting machine, Design rolls etc.

Gold side production is an India based leading manufacturer and exporter of jewellery making machinery & equipments since 1992. The brand name of company is “LION GOLD SMITH”. The founder Mr. Dineshbhai Rabadiya has continuously strived to achieve excellence in qualitative production. Gold Side is in to manufacturing of Special purpose rolling mill, Tube forming machine, Jewellery polishing machine, faceting machine, Design rolls etc.The company’s range of products includes small, medium & special purpose rolling mills, Bangle sizing, Ring sizing machines, S.S.Media for polishing machine. The Company adheres to kaisen quality control system measure at each production process that makes our final product Gold smith tools and Machinery most durable and leads to customer satisfaction. ‘Our customers are our backbone and we are always taking prompt action in executing their requirements of jewelry making machinery and equipments’ says Rabadiya and adds, our corporate philosophy includes “Our utmost mission is to provide wide range of Gold smith tools, Jewellery making machine & Equipments in excellent quality of product & service.” Gold Side Production generates new ways that will always lead the jewellery making industry. We would like to pursue and explore the ocean of infinite possibility with our customer. We will provide our customer’s with unique products and information that will be of great help in making jewellery, products of precious metal and their related products. |

April-June 2014

Offering 3D PRINTING revolution in Jewellery

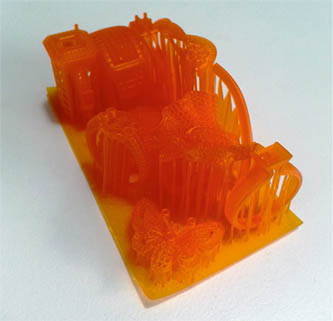

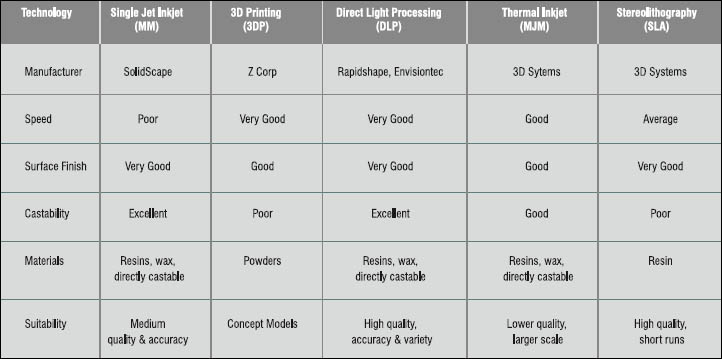

3D Printing is a revolutionary technology that is rapidly transforming the jewellery landscape. From design to production to retailing, the 3D Printing wave is sweeping across the industry and promises to become the de facto process in jewellery design & manufacturing. 3D Printing machines build 3D objects (rings, pendants, bangles, murtis) directly from CAD models. They do this by digitally slicing the 3D model into thin layers which the machine then builds one layer at a time to make the physical object. These models are made of a variety of plastic resins, wax, and directly castable resins. These prototypes can then be used for investment casting and other metal production processes. 3D Printing brings major advantages: • Create impossible, never-seen-before designs or highly customized pieces, even if its just one. • Make them in record time - hours to days only • Save huge on development and production costs • Develop lean and flexible business processes   Imaginarium has pioneered the use of RP and 3D Printing technologies in India since 2009 and is the largest 3D Printing service bureau in India. We currently serve over 2,500 business partners across the globe. In addition to having the broadest range of service offerings for jewellery product development, we also partner with you to understand your business and how best to implement 3D Printing into it, from machines & materials, to services & maintenance. 3D Printing brings the focus back on your imagination and creativity. Modern jewellers are required to innovate quickly, reduce lead time, and showcase broad, flexible portfolios. Customization is also becoming key to serving customers all over globe. It is precisely this environment that the power of 3D Printing can truly be realized. “ The rising price of raw materials has made the consumer and manufacturer deeply cost conscious. Adopting 3D Printing methods makes it possible to create contemporary, lightweight, and afforabale designs that economize material, withourt compromising on quality. In fact, the technology has truly levelled the playing field in terms of quality. Today, products made by bespoke designers, imitation jewellers, and plastic jewellery manufacturers, are comparable in quality – giving gold and precious metal manufacturers a run for their money. “

Imaginarium has pioneered the use of RP and 3D Printing technologies in India since 2009 and is the largest 3D Printing service bureau in India. We currently serve over 2,500 business partners across the globe. In addition to having the broadest range of service offerings for jewellery product development, we also partner with you to understand your business and how best to implement 3D Printing into it, from machines & materials, to services & maintenance. 3D Printing brings the focus back on your imagination and creativity. Modern jewellers are required to innovate quickly, reduce lead time, and showcase broad, flexible portfolios. Customization is also becoming key to serving customers all over globe. It is precisely this environment that the power of 3D Printing can truly be realized. “ The rising price of raw materials has made the consumer and manufacturer deeply cost conscious. Adopting 3D Printing methods makes it possible to create contemporary, lightweight, and afforabale designs that economize material, withourt compromising on quality. In fact, the technology has truly levelled the playing field in terms of quality. Today, products made by bespoke designers, imitation jewellers, and plastic jewellery manufacturers, are comparable in quality – giving gold and precious metal manufacturers a run for their money. “Kamlesh Parekh Director Imaginarium (india) Pvt Ltd Visit us at IIJS 2014 – Hall No. 1 – Stall No. 1J102  A comparison of various 3D Printing technologies for jewellery prototyping |

April-June 2014

Valued consultancy Services for the Gems & Jewellery Industry

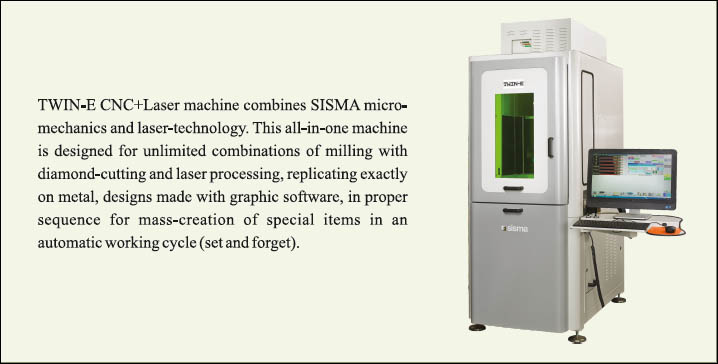

N Jewellery Techniques (NJTPL) was established under the able guidance of NARIMAN H. WADIA, a well-known figure in the jewellery industry since the last 56 years. It is currently being headed by its Director, MEHERNOSH D. PRINTER. When NARIMAN H. WADIA, entered into the jewellery industry, jewellery was traditionally being manufactured manually with obvious constraints. With his revolutionary application of ideas and introduction of machines for mass production of jewellery, NARIMAN H. WADIA provided a quantum leap in production capabilities and quality. He has several credits to his career. Having studied jewellery design at the London County Council Central School of Art, he served on the Research and Development Committee of the GJEPC and is currently a nominated appraiser of the Trade Advisory Panel for the Gold Jewellery by the Commissioner of Customs (Airport). MEHERNOSH D. PRINTER, who started his career as an under-study of Nariman H. Wadia, gained a strong knowledge of jewellery manufacturing processes first hand, from his mentor, accumulating valuable experience in all aspects of jewellery manufacturing over several years. In addition, he has a strong educational background in Finance. N Jewellery Techniques (NJTPL) gives consultancy for setting up complete factories for jewellery manufacturing companies from inception to completion, as also assists in solving problems related to all jewellery manufacturing processes. In addition NJTPL also represents some of the finest machinery manufacturers worldwide for every aspect and stage of jewellery manufacturing, selectively choosing the best equipment available for the specific needs of our clients for the present and foreseeable future. NEW - With the world now adopting 3D Printing in virtually every imaginable field, the application of Laser Sintering and 3D additive printing was inevitable in the jewellery field. NJTPL also brings in current leading companies having the above technologies to its esteemed clients. As technology develops further, we will proactively introduce the same periodically to our clients.  At present, NJTPL enjoys a major share in the market for :

At present, NJTPL enjoys a major share in the market for :Welding Lasers from SISMA S.p.a., Italy - Various models for welding silver, gold, platinum, which can work continuously (In-built heavy- duty chiller system) for up to 22 hrs. per day for assembly, repairs, and welding of parts. Marking Lasers from SISMA S.p.a, Italy - Various models can mark text, pictures, logos, etc,. on flat, curved and round surfaces with automated Rotary systems. Thinnest Laser beam of 10 microns. Rhodium Plating Chemistry from Umicore Galvanotechnik GmbH, Germany - Brightest plating processes for everlasting brightness and problem - free chemistry. All assistance provided for setting up the plant up to the finished product, for plating departments.    |

April-June 2014

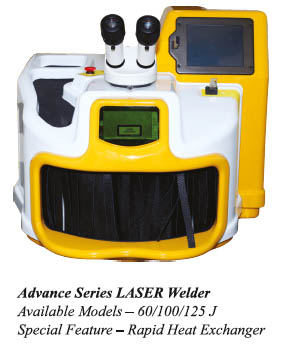

With the increasing use of mechanization in different stages of the jewellery manufacturing process in India, the demand for more compact and efficient models that are specially designed to operate in Indian conditions is on the rise. Italian-manufactured Advance Series Laser Welder  DM IMPEX who introduced OROTIG in India, has recently launched a new Advance Series Laser Welder with unique features specially customised for Indian conditions. This can be powered by 60/100/125 Joules and comes with some key features that perfectly match the needs of Indian manufacturers.

DM IMPEX who introduced OROTIG in India, has recently launched a new Advance Series Laser Welder with unique features specially customised for Indian conditions. This can be powered by 60/100/125 Joules and comes with some key features that perfectly match the needs of Indian manufacturers.The machines are manufactured exclusively for the company by OROTIG, one of the leading Italian manufacturers of machines using LASER technology. The new machine comes with an inbuilt ‘Rapid Heat Exchanger’ that ensures faster cooling. By using the “Advance” Laser Welder, a manufacturer will be able to boost output as a result of better duty cycles. More efficient cooling also ensures longer life for the machine. Another optional feature is the External Video connection with HD Camera. A manufacturer has the option of plugging in a lager external monitor. This means that the operator can view the work in larger size images ensuring greater accuracy in operations. Another innovation is the stand alone “WORKSTATION” LASER welder whose height can be self-adjusted by the operator, and a non-stop power release mechanism. The LASER pulse shaping programme also offers five pre-set wave shapes which allows for greater ease of operations in the case of complex pieces and metals.  DM IMPEX also offers the 20W Open LASER marker. Thanks to its open shape, operators can more easily access the laser marking area and find it easier to use the marker. This machine is ideal for marking text, graphic patterns, drawings, images, and also to do LASER markings on curved surfaces like rings, bangles and bracelets. The marker has provisions for Suction, is good for Marking on Flats & Tops and can be used for Deep Engraving & Cutting. It can also be provided with continuous feeding mechanism as options for markings and cutting.

DM IMPEX also offers the 20W Open LASER marker. Thanks to its open shape, operators can more easily access the laser marking area and find it easier to use the marker. This machine is ideal for marking text, graphic patterns, drawings, images, and also to do LASER markings on curved surfaces like rings, bangles and bracelets. The marker has provisions for Suction, is good for Marking on Flats & Tops and can be used for Deep Engraving & Cutting. It can also be provided with continuous feeding mechanism as options for markings and cutting.These machines are compact and lightweight, ideal for doing small and fine details, are fast and efficient and therefore low cost and low maintenance. They are useful both for smaller workshops, Hall Marking centres and large factories. Spanish made ‘Zero Metal Loss’ Gold & Silver Grinding & Polishing Machines In a highly price-conscious market like India, every manufacturer seeks to gain a competitive edge by achieving greater operational efficiency. Introduction of machines that save in terms of time, manpower, electricity, etc are therefore high on the agenda. And when such machines have built in systems for recovery so that there is Zero Per cent Metal Loss, it is clearly an added bonus. DM IMPEX, which markets a range of products from leading Spanish manufacturer HISPANA, offers state-ofthe- art machines (GPG and PMG) which are Grinding and Pre-polishing Systems for Silver and Karat Gold Alloys. These dual action systems help the manufacturer save space and electricity. The grinding and polishing results are amazing. The labour costs are at a minimum and consumables used are low. The newer versions of these machines (Step 2) help the operator reach recessed areas, insides, filigree and work on jewellery with stones cast in place. They do not affect the stones, enamelling and non-conductive surfaces, allow for freer designs as it follows the geometry of your design and does not round prongs or angles. Other HISPANA products that could be used by jewellers include Mark IV/Mark IV Plus/Mark Robot: Innovative line of wax injectors Mininvest/Starmix: More advanced investment mixers under vacuum for gold/platinum. Solid & reliable mixers for small, medium & large productions. Starcast/Starcast Plus: New vacuum-pressurised medium frequency casting machine D-Invest: Equipment to remove investment from flasks and trees Starmelt: Medium frequency melting furnaces   |

April-June 2014

High-end Technology to Analyse Precious Metals

Oxford Instruments India Pvt. Ltd. is a wholly owned subsidiary of Oxford Instruments Plc (listed in the London Stock Exchange) and supports key customers in industry, research and academia. Oxford Instruments India offers range of high quality products for Industrial Analysis and Nano technology. Innovation has been the driving force behind Oxford Instruments’ growth and success for over 50 years, and its strategy is to effect the successful commercialisation of these ideas by bringing them to market in a timely and customer-focused fashion.

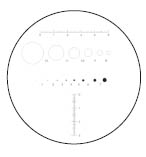

Oxford Instruments India Pvt. Ltd. is a wholly owned subsidiary of Oxford Instruments Plc (listed in the London Stock Exchange) and supports key customers in industry, research and academia. Oxford Instruments India offers range of high quality products for Industrial Analysis and Nano technology. Innovation has been the driving force behind Oxford Instruments’ growth and success for over 50 years, and its strategy is to effect the successful commercialisation of these ideas by bringing them to market in a timely and customer-focused fashion.Head quartered in Mumbai, it is one of the few companies in India to set up a demonstration lab for Industrial Analysis products where distributors and customers can analyse samples, demonstrate systems and be introduced to new technologies. This lab houses a range of analysers that span applications from metals analysis, to low sulphur in petroleum, to gold coating analysis. In order to control costs and quality, jewellery and other precious metals items (e.g. coins, high-end cutlery) are tested for composition analysis many times over their life-time, from the raw materials to the finished product and to the recycling. The analysis is also required to verify authenticity, and determine value. The high price of precious metals such as gold (Au) and platinum (Pt) means that a small difference in their contents means a large difference in the product’s value. Traditionally jewellery and other precious metals alloys have been analysed by fire assay. This is a highly accurate technique, but is lengthy and destructive. Samples are often sent to an off-site laboratory, and results can take days to return. Because of these disadvantages, X-ray fluorescence (XRF) is also used when certification (e.g. hallmarking) is not required, providing non-destructive multi-element analysis and results in seconds!

With over 25,000 units installed world-wide for precious metals analysis and coatings thickness applications, the X-Strata Series of coating thickness benchtop analysers offers outstanding precision and accuracy. These compact, rugged and reliable quality control analysers can perform elemental analysis without any chemicals and in a totally non-destructive technique. The X-Strata920 is an instant assayer with pin-point accuracy which can analyse the purity of Gold between 8 - 24 Karats. The miniwell base accommodates analysis of small to large samples – from gold links from 0.3 mm diameter to large plated samples up to 160 mm high. This requires minimum user training to confirm Karat content for ensuring correct pricing. It can perform composition and coating thickness analysis for elements from Ti22 to U92. Oxford Instruments’ field proven, microfocus 50 W X-ray tube, and high resolution, sealed Xenon gas filled proportional counter delivers outstanding precision and laser focus, with simple “point and click” function to automatically adjust focal distance (0.5”), improves system reproducibility and minimises user-to-user variability. The handheld XRF analyser X-MET7000 Series combines the Oxford Instruments’ 40kV X-ray tube, and high performance silicon-drift detector (SDD), providing excellent accuracy and repeatability. With minimal operator training and no requirement for a power source this instrument can be used straight out of the box. This is a rapid, reliable portable analyser which provides accurate and repeatable analysis of precious metal alloys such as jewellery items. The X-MET enables the user to verify products authenticity and value in seconds, with no sample preparation: there is no grinding of sample (no material loss or damage), and no use of chemicals. The X-MET7000 eXpress can provide precious metal analysis in as low as 2 seconds! Precious metal analysis, such as composition analysis, is required to ensure quality and value of the product. Precious metals such as Gold (Au), Platinum (Pt), Silver (Ag) and Rhodium (Rh) are widely used in the manufacture of jewellery and fashion accessories as the main components or as a thin coating for surface finish. It is essential to analyse the composition and/or plating thickness at the time of manufacture, casting, selling, buying or recycling in order to ensure the quality and value of the final product. This is even more important and critical while testing gold jewellery for the Karat value. Additionally, analysing precious metals for toxic elements such as Lead (Pb) in jewellery means that unsafe items can be removed from the supply chain. Apart from the jewellery market, Oxford Instruments Industrial Analysis offers products suitable for materials analysis to thickness gauging, incorporating the latest field proven technology, coupled with over 30 years of experience in designing, producing and supporting world class instruments. With leading products and a global sales and service network, Oxford Instruments Industrial Analysis continues to explore innovative ways to deliver instrument solutions for faster and easier measurements and aims to pursue responsible development and deeper understanding of our world through science and technology. Its products, expertise, and ideas address global issues such as energy, environment, security and health. Visit www.oxford-instruments.com for more information on the company and its products. |

April-June 2014

Setting Standards with Indegenious world class products with in house Research & Development

Citizen Scales (I) Pvt Ltd is one of the global players having its own indigenous Manufacturing Unit with in-house Research & Development team. The journey begins only with XRF Gold Purity Machine in IIJS-07 & today CITIZEN is proudly owner of German Technology for Gold Purity Machine. Apart from Gold Purity Machine Citizen having Technological tie up for World's best Jewellery equipment products like Fiber Laser Markers, Desktop Laser Spot Welding Machines, Engraving Products, and Ultrasonic Cleaners. Thanks to advance technological breakthrough Citizen is exporting to more than 70 countries worldwide including USA, Europe, and South East Asia etc. Our one of the fastmoving product is Cube which is launched in 2012 and supplied across India as well other countries. Once again ,in IIJS 2013 , we launched our one more new product Cube-Pin with USB . A one more landmark….  Principal of X-ray Measurment

Principal of X-ray MeasurmentHigh energy photons emitted by a X-ray tube interact with metal. The high energy photon is absorbed by an electron of the atom. This electron is accelerated and forced to leave the atom. The so created hole in the structure of the electron shell is filled up by an electron of higher energy. The difference is energy between the leaving electrons position and the filling up electron may leave the atom as a photon of defined energy or as an electron. In the case of a leaving photon this process is called X-ray fluorescent and the energy of the leaving photon is characteristic for this atom therefore for the element. The electron shells of an atom are called. K-, L-, M-shell. Filling up a hole in the K-Shell creates, Kradiation (Ka if the filling up electron has is origin in the Lshell, Ka if the filling up electron has is origin in the Mshell). Filling up a hole in the L-shell creates L-radiation and so on. Only K and L radiation is on interest because the energy of K and L radiation is in the region which can be detected with standard detectors. .   Fiber Laser Marking Machine (CFM-10 & 20)

Fiber Laser Marking Machine (CFM-10 & 20)Technology: Based on Ytterbium Finer Laser technology Which is highly reliable laser source. Marking: Able to mark all metal and some non-metal materials. marking minimum lines width of 0.03 mm, minimum height of 0.3 mm for english characters and depth of up to 1mm. Flexibility: Optional Motorised Rotary Marking Device for accurate & continuous 360º marking inside or outside bangles & Rings. Compatibility: WINDOWS based marking software, able to read CORELDRAW, AUTOCAD, PHOTOSHOP and other commonly used graphic files, such as AI, PLT, DXF, BMP, JPEG  Laser Welding Machine (CML-W150)

Laser Welding Machine (CML-W150)Technology: The Principal of Laser welding machine for jewellery is thermal conduction, namely, the laser radiates the surface of the part, and the heat on the surface expands inside through heat conduction. by controlling parameters such as laser pulse width, energy, peak value and repeating frequency, the part will melt, and thus forming specific molten pools. Due to its unique benefit the product has been successfully applied to gold and silver jewellery processing, and welding of small-sizea parts and porosity filling.  FoRza Laser Welding Machine (FoRza-160)

FoRza Laser Welding Machine (FoRza-160)Technology: Citizen has launched FoRza from a technological point of view. It takes a concentration of six year study in the electronic, optical and mechanical field. The new digital microprocessor, works 100 times faster than traditional systems. and is able to measure the high energy precisely, analysing it and sampling it every 100 micro seconds. All of this makes welder FoRza a powerful Welder laser, while at same time constant and very precise in the repetition of the shots.. Features • It’s the first laser controlled by a digital microprocessor(D.S.P) • Real time and automatic regulations of the power supply. • Double light LCD • Touch Screen Shutter. • 30 Hz frequency • Automatic control of the laser lamp, with consequent automatic adjustment of the energy. • Integrated webcam • Better cooling chamber • Powerful cooling system.  Micro Balance (CM Series)

Micro Balance (CM Series)Technology: Citizen Micro Balances is based on Electro magnetic force compensated principal. The compensated principal is superior to conventional systems due to improved dynamic & static performance. Convenience: Citizen Micro Balances equip with Touch Screen Display with user friendly menu. User has access to multiple function & measuring units which allow user for smooth working requirements. |

April-June 2014

Complying with International Standards with Quality products

received by Mr. Vijay Gopani in field of Fittings and Findings “ Today, M/s. Harsh Precious Metals Pvt. Ltd. supplies products of BIS and Hall Marked standards with unlimited range of products in fittings & findings such as Butterfly, Illusion, Cufflinks, Omega, Ear Clips, Ear Hoop Post, Joints & Catches, Pearl Posts, Pad Post, French Ear Wire, Lever Back, Fusion Wire, Friction Ear Nuts & Post, Threaded Ear Nuts & Post, Rubber Post, Clutch Backs, Single Line GB, Double Line GB, 4 Prongs, 6 Prongs, Centre heads, Detachable Pendant Tops, Pendant Bail, Pendants & Clusters, Catches, Top & Side Opening Broach Pin Catch, Snaps & Channels, Rectangular Flat & Convex End Caps, Spring Rings, Lobster Clasps, Shiny Beads, Chain Finding, Chain Tag, etc. Currently, HPM has come up with complete range of Hollow Seamless Tubing which can be used as semi finished product for manufacturing of Hollow Bangles, Hollow bracelets & Hollow earrings. The basic concept of M/s. Harsh Precious Metals Pvt. Ltd., an ISO 9001:2008 Company is to fulfil the requirements of Jewellery Industry - a unique quality product. Nothing less than supreme quality with best possible technical support and after - sale service is our motto and to develop standardized and customized products to serve global market is our main quality objective. Our company continuously improvises the manufacturing process & identifies and understands the changing market & customer's requirements, while catering to their needs accordingly. We draw inspiration from linear structures, professional guidelines and to a certain extent our designers are even influenced by modern contemporary art says Mr Gopani, the founder Director of Harsh Precious Metals Pvt. Ltd. M/s Harsh Precious Metals Pvt. Ltd. aims to consistently deliver world-class quality in every aspect and ensure that its products would be the natural choice of discerning customers across the globe. Therefore, we have built quality into all the processes throughout the organization. We follow stringent quality measures at our unit and ensure that our products are cross- checked, once they have been manufactured. Thus, we have achieved enhanced customer satisfaction and world class quality products through stringent quality systems that comply with international standards. Mr.Vijay Gopani the founder Director of Harsh Precious Metals Pvt. Ltd. is a well known personality in the gems and jewellery sector. He has won Praises and accolades equally from the industry members and is an example for honest business practices combined with entrepreneurial excellence. Mr Gopani’s enthusiasm and visionary qualities in business has resulted in the exponential growth of the enterprise. |

April-June 2014

Supply Chain Management System for Jewellers

A Complete Supply Chain Management Software crafted for Jewellery Retail industry – to manage Jewellery Retail Chains with Multiple Distribution units, Multiple Retail stores in various geographic locations. Indsoft Jewels SCMS helps in monitoring and analyzing movement of each and every items in any retail store and make distribution of items seamless with its fully automated requisition generation & procurement planning and distribution management system. Facilitates auto indent generation, procurement & production planning. The software gives you freedom of consolidation of multiple distribution units, retail units, manufacturing units and export oriented units based on its tax structure, administrative and geographical specifications. In distribution management branch requisitions are pooled up & based on the available stock, distribution can be managed effectively and efficiently. Store level operations are fully integrated and centralized with distribution units. Barcodes are generated in the Distribution units or Head office and same barcodes can be transferred to outlets online which enables tracking of items at any point of time. The software facilitates the adjustment of customer advances across the branches, receipt & closing of gold saving schemes and subsequent adjustment of the same in billing. Sales return can be adjusted across retail outlets. The CRM module in supply chain environment enables the customer to use loyalty cards in any outlet. Replenishment Optimization Indsoft’s requisition management modules enables you to make decisions about procurement cycle, quantity levels product roll out in each store. It helps you to reduce non moving inventory and to increase the inventory of fast moving items and ensures you have the right inventory based on the market requirement. Retailers can plan demand variations in supply chain by adopting innovative automated model to forecast consumer demand. Inventory Optimization Inventory optimization system helps you to define inventory strategies based on various factors like geographical location of stocks, tax structure to produce smarter decisions on manufacturing and distribution and enables you to optimize planning, production and procurement.  Distribution Optimisation Distribution Optimisation module helps you to make decisions based on realistic forecast of market demand. It enhances sales and operations planning to achieve corporate goals. Enhances supply chain events through automated monitoring. Retail chains can enhance customer satisfaction by producing and procuring products and moving them to right distribution units at the right time. Distribution management system can make sure that products are moved to the right store at the right time. Other Indsoft Services Indsoft Retail Management System for Jewellers Indsoft’s industry specific Retail Management Solutions helps you to manage all aspects of your store management with pinpoint accuracy. Indsoft Retail management System (RMS) helps you with efficient inventory management , replenishment based on ROL or based on the movement of products, customer /supplier order tracking, consignments and approvals and moreover it is integrated with Indsoft’s state of the art Financial Accounting System and HR & Payroll Management System. Indsoft’s industry specific RMS manages inventory types included individual items, kits, sets, assembly etc. It tracks movement of items, supplier’s and manufacture’s histories, costing and delivery standards. Generates sales and purchase analysis based on the trends, category, supplier and other attributes and these analysis can be exported to MS Excel, XML, PDF or directly forward to the mail box. Its scalability allows you to keep the same software, as your business grows into multiple chain stores. RMS is easily upgradable to our full fledged Supply Chain Management System. Indsoft Production Management System for jewellers Production management ensures full or optimum utilization of available production capacity. The main objective of production management is to produce goods and services of the right quality, right quantity, at the right time and at minimum cost. Our Jewellery Production & Manufacturing Software solution is designed to meet the needs of progressive make-toorder and mixed-mode manufacturing companies.Indsoft Jewellery Production Management enables you to manage lifecycle of an item from its wax design to different stages of production and upto finished product. Indsoft keeps track of customer order, job card, material movement in each department, material usage,wastage and losses for each worker, job status and inventory with each worker. Scheduling is key to efficient operations. With Indsoft you can identify bottlenecks and react in real-time to unexpected production problems. You'll know what job to run next, when to promise the customer’s order, and what machines can get it done the fastest. . It also gives power to manage manufacturing business with complete ease. Indsoft CRM (Customer Relationship Management System) for Jewellers Customer Relationship Management (or CRM) is a phrase that describes how your business interacts with your customers. CRM is also about what you do with that information to better meet the needs of your existing customers and identify new customers, resulting in higher profits for you. Customer relationship management (CRM) is a management strategy that unites information technology with marketing. Indsoft CRM module enables you to track and organize its contacts with its current and prospective customers, information about customers birthday, wedding anniversary etc and customer interactions can be entered, stored and accessed by employees in different departments. It also helps you to maximize repeat business opportunities by anticipating your existing customers’ needs,identify your best customers, identify potential customers, target marketing campaigns/material and promotions. Promotional schemes like redeemable coupons, festival offers and gift vouchers based on sales amount, sales weight etc and discount settings based on gold rate, making charges etc can be made. Provision for multi type loyalty card is also available. Automatic sending of messages on sale generation, scheme receipt, order placing, birthdays anniversaries etc are included. Various analysis like customer interests, customer spending pattern, PR & media analysis etc,. are provided. CRM aims to improve services provided to customers, and to use customer contact information for targeted marketing. |

April-June 2014

The Only Cloud based IT Backbone for Diamond Industry